Forensic Engineering Failure Analysis Specialists & Expert Witness

areas of expertise

For over 30 years, Gilmore Engineers Pty Ltd has been a leader in forensic engineering including the investigation and analysis of accidents and failures. We are one of only a few mechanical engineering consultancy companies in the world specialising in failure analysis. We provide services to the legal profession: corporations, insurers and individuals. Typical failures include machinery or system failures resulting in property damage, personal injury or loss of life.

Specific services include acting as an expert witness in a Court of Law; analysis and redesign of failed components; experimental testing; design auditing; Finite Element Analysis (FEA), eg material stress analysis; Computational Fluid Dynamics (CFD); material testing; corrosion analysis; fire investigations and the auditing of safety standards.

Further services include the analysis of motor vehicle accidents to establish the probable cause; forensic analysis to assist with criminal investigations such as arson and murder; Intellectual Property defence support (copyright and patents); product liability reviews and experimental testing.

- Expert Engineering Opinion with a comprehensive report

- Over 1500 Expert Witness Reports have been prepared over the past 30 plus years.

Motor vehicle accident analysis and reconstruction, of incidents involving a single vehicle or multiple vehicles, including passenger cars, prime movers and trailers, trucks, motorcycles, marine vessels or buses.

- Pre-incident speed analysis

- Head-on impacts

- Vehicle rollover

- Skidmark analysis

- Headlight and tail light on/off analysis

- Pedestrian impacts

- Determination of seat belt use

- Stopping distances calculation

- Position of vehicle pre-impact

- Motorcycle and Bicycle impacts

- Tyre, suspension, brakes, steering and other component failures

Inspection and root cause analysis of significant machinery failures and cracking.

- Large engines: trucks, plant, marine vessel

- SAG mills: cracks, bearing failures, design audits

- Drill rigs

- Rock hammers

- Conveyors

- Haul trucks

- Excavators

Cranes, Elevating Work Platforms (EWP) and lifting equipment failures and root cause analysis.

- Crane dropping load

- Mobile crane crashes

- Crane collapse

- Injuries and fatalities

- Operator error

- EWP collapse

- Failing from EWP bucket

- Lifting equipment failures

Occupational health & safety, a system of work assessments and investigation and analysis of injuries and fatalities from;

- Workplace incidents

- Cumulative trauma disorders

- Slip & falls

- Crushing impacts

- Amusement rides

- Ergonomics

- Noise and vibration effects

- Ladder failures

- Swimming injuries

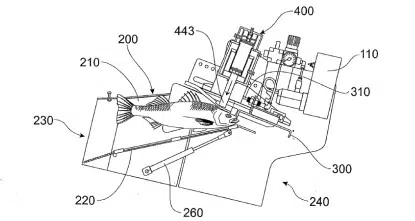

Review and assessment of IP claim, including patent and copyright disputes.

- Fish harvesting machine patent

- Industrial conveyor belt system

- Heavy haul trailer design copyright

- Heavy vehicle suspension performance patent

- Building product patent infringement

- Sunshade and umbrella patents

- Playground products

- Engineering comparisons of technology

- Vehicle equipment patents

Building, machinery and motor vehicle fires & explosions. Analysis and ignition source identification.

- Crane engine fire

- Gas well explosion

- Excavator fire

- Underground mine explosion

- Hotel/backpacker fire

- Car engine fire

- Arson investigations

Consumer and industrial product analysis, testing and assessment of compliance with standards.

- Swimming pool heating system

- Industrial steam boiler

- Furniture failures

- Angle grinder

- Drills and drill presses

- Ladder failures

- Kitchen appliances

- Curling iron

Helicopter and Aeroplane accident reconstruction and analysis of component failures.

- Helicopter bearing failure

- Aeroplane engine failure

- Helicopter drive train failure

Design reviews, testing, failure analysis, and checking for compliance with Australian, or International, Standards, Codes, and Workplace Safety Requirements

- Farming Machinery

- Industrial Equipment

- Mining Equipment

- Motor Vehicles

- Vehicle Modifications

- Nuclear Facilities

- Kitchen Appliances

- Consumer products